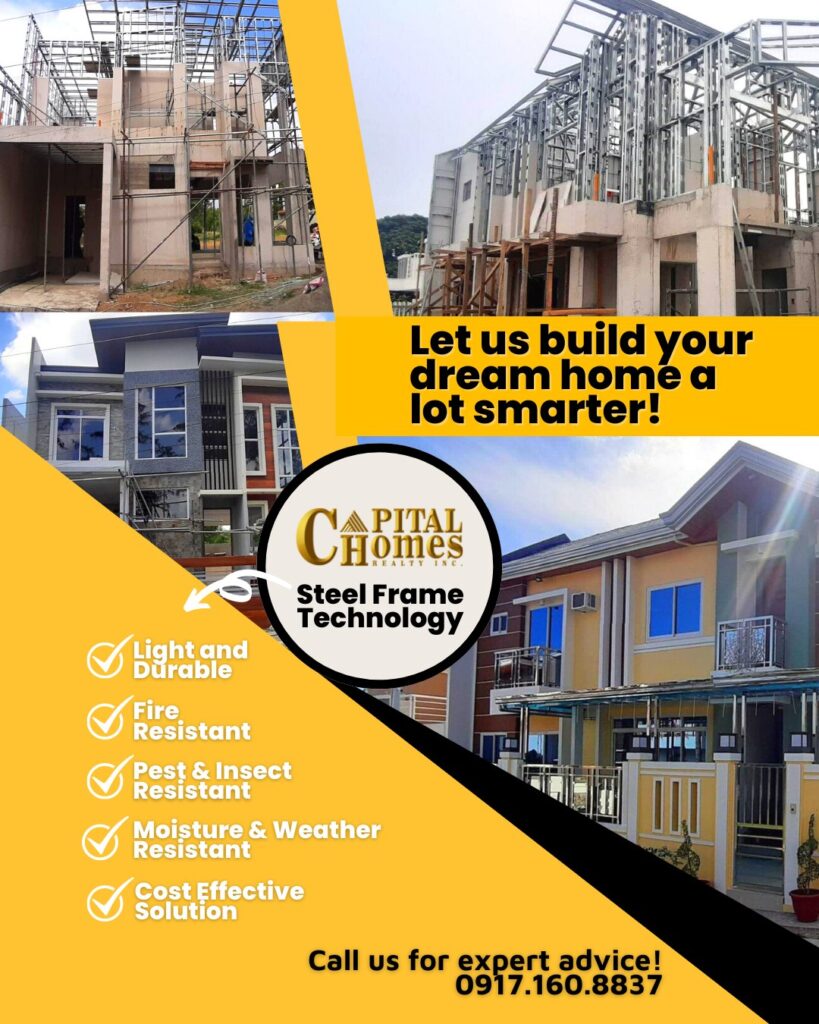

The management’s more than 30 years of combined experience in dealing with real estate and construction management has made us realize the need for a revolutionary concept of building structures in a more efficient and affordable way. This paved the way for our Steel Framing Technology department which introduces a new approach to the construction of houses and other structures. Our construction methodology is NOT the same as the conventional brick and mortar, rather, we embrace the important role of technological innovation using a proprietary system registered under the National Housing Authority’s (NHA) Accreditation of Innovative Technologies for Housing or AITHECH. This department was developed to address the ever- increasing requirement for the country’s housing sector which is also in line with the company’s mission of providing quality, decent and affordable housing for every Filipino.

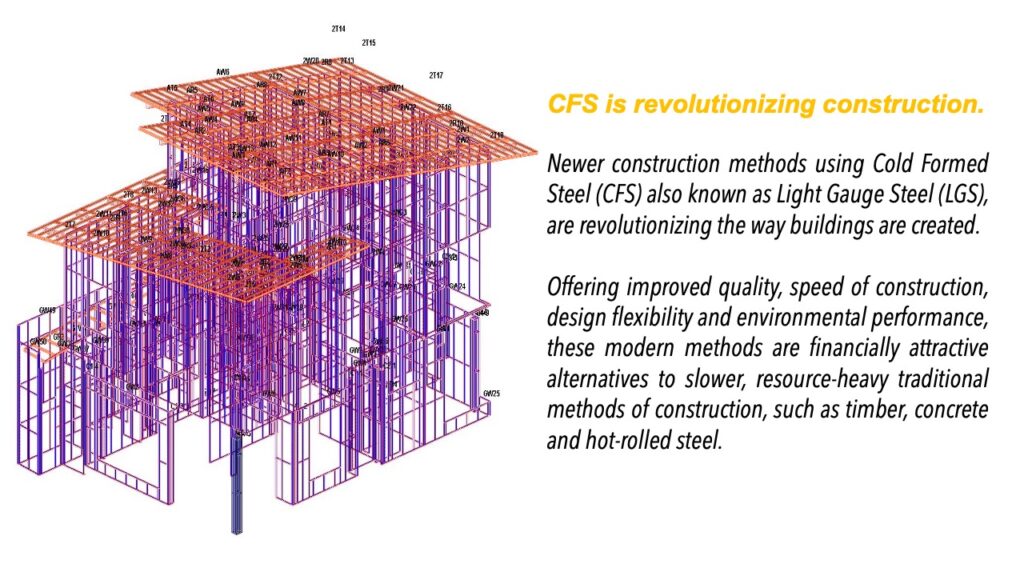

CapitalHomes Realty Inc’s Steel Framing Technology is in partnership with METALYTE Construction and Development Corporation (MCDC) whose company was borne out of more than 10 years’ experience and knowledge by its Principals in the housing and construction industry. Together with METALYTE, we use newer construction methods using Cold Formed Steel (CFS) also known as Light Gauge Steel (LGS). Our technology produces lightweight steel frames by using state of the art computerized roll forming machines operated by means of a high-tech software specifically customized for the Philippine housing set-up. These methodologies are revolutionizing the way buildings are created. Offering improved quality, faster speed of construction, design flexibility and environmental performance, these modern methods are financially attractive alternatives to slower, resource-heavy traditional methods of construction, such as timber, concrete and hot-rolled steel.

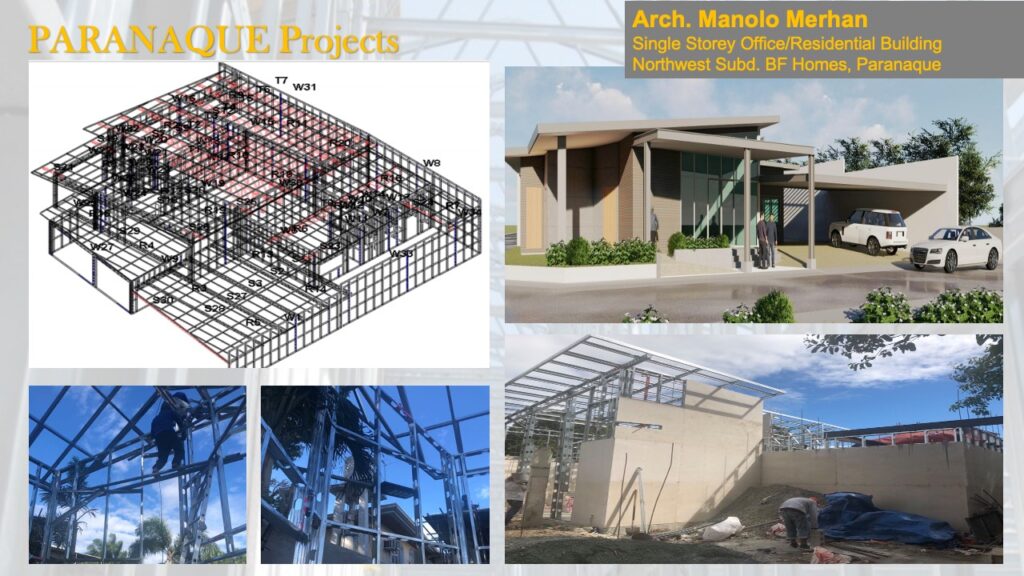

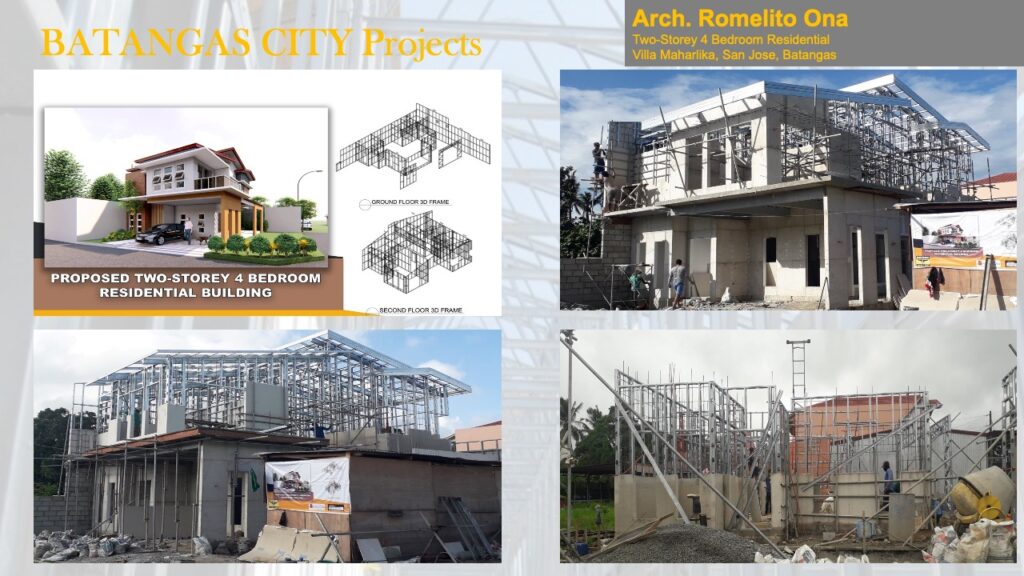

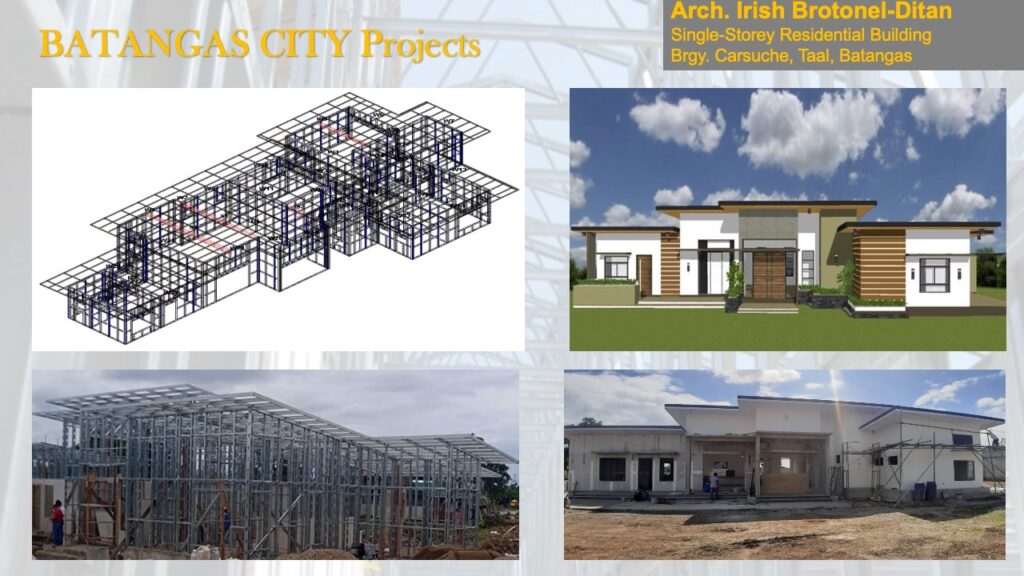

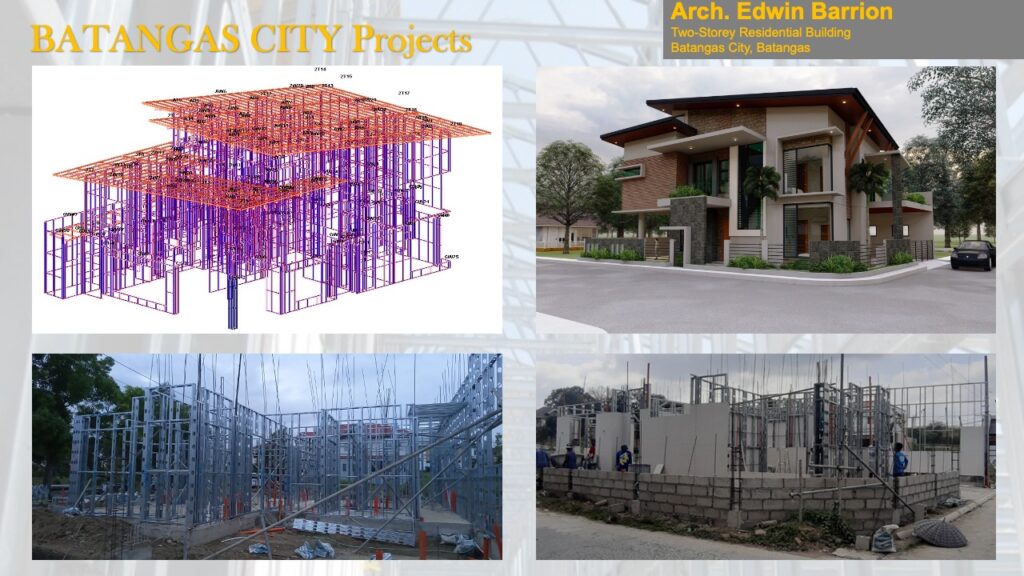

Production Process

The production of steel frames involves the use of a computer-controlled roll forming machine

and computerized punching, countersinking and cutting. Steel coils of Zincalume or galvanized coated sheet steel are fed through a roll forming machine to produce channels.

Prior to roll forming, the details of the house frame to be manufactured are transcribed into the computer software package. The software package provides data on cutting and punching which is then fed into the computer which controls the roll forming and punching operations.

The end result is that each steel frame member (channel) is cut to size with holes punched to enable members to be later riveted together. These are the components, which can be transported as a flat (strapped together) packed.

Each member is printed with job and part number for ease of assembly eliminating the need for costly time jigging. The roll form machine can be programmed to continue the repetitious production of buildings as many times as required.

A house frame of 160 sqm can be produced through the roll form machine in three (3) to four (4) hours. Each section of wall and roof are packaged in individual bundles and have accompanying computer drawings for ease of identification and erection.

The drawings are simple and allow members to be assembled using hand held pneumatic riveting machine which installs high shear strength rivets or screws.

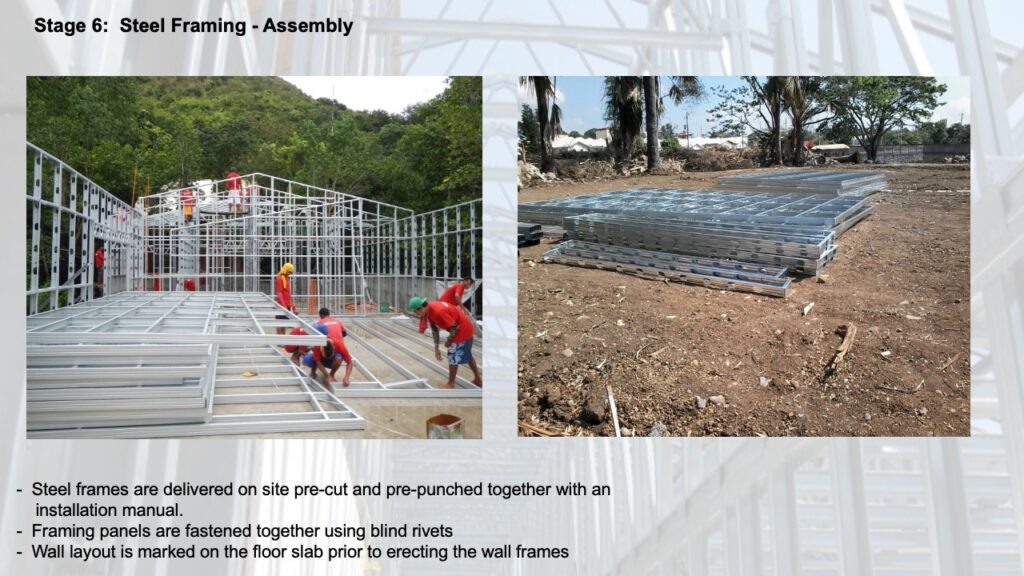

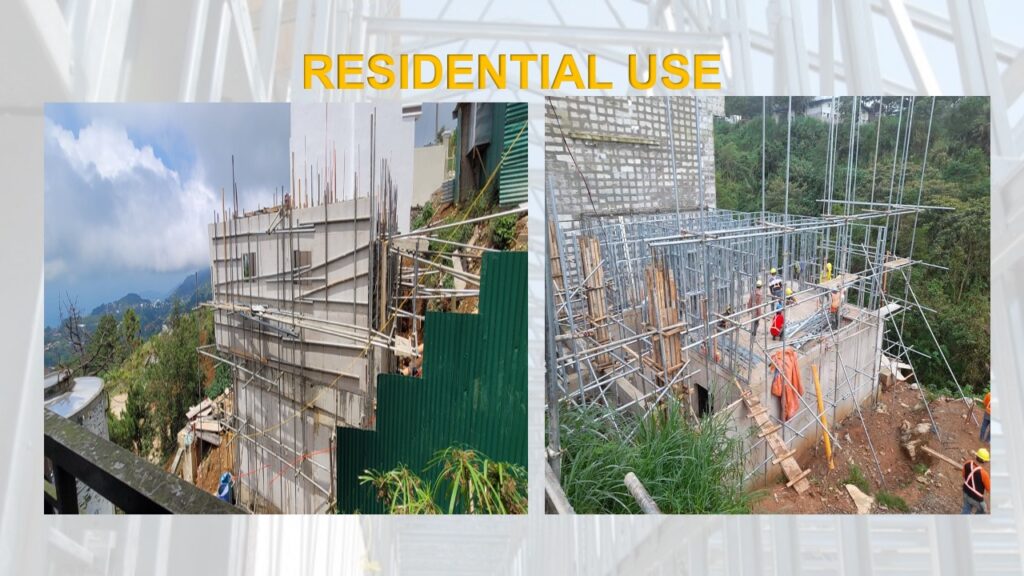

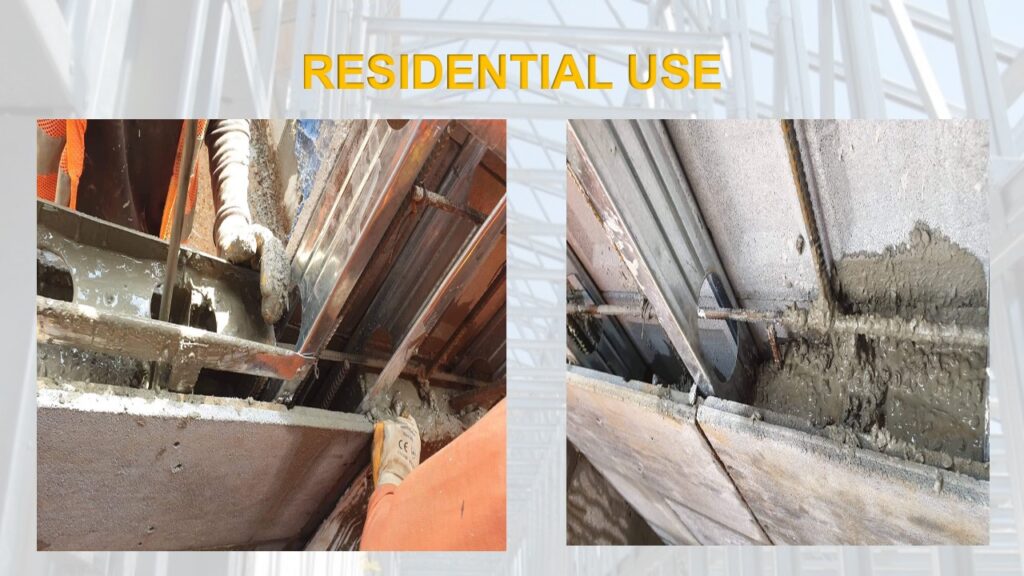

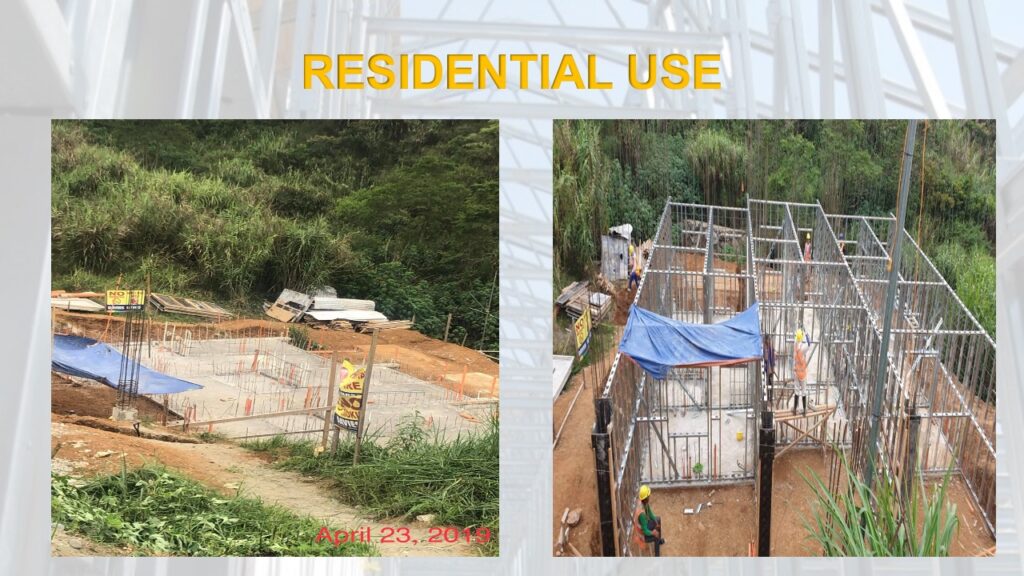

Once the steel frames are assembled together at the site, it will be bolted to the structure’s foundation or based. The purlins are then attached with self-drilling fasteners. The colored roof panels or sheathing are attached to the purlins. The side wall and/or end wall studding is installed. Finally, apply the exterior finish of choice to complete the structure’s shell.

The concept of steel-framed house is not new in Asia and in the Philippines. Though, CAPITALHOMES and METALYTE, through series of innovations, has come up with much efficient approach that significantly reduces costs and production time by more than half.

METALYTE fabricates and supplies our frames and trusses for houses from high tensile g550 galvanized or zincalume steel coils, designed, cut and assembled with the aid of a specialized computer software and roll former machine. The steel frames are customized according to different project requirements and each house plan is assigned a computer file processed by the software, which commands the roll former to roll steel into channel sections (members) with holes punched-in to enable each to be riveted together into a whole house frame. Every piece of stud, plate and nogging on the walls, as well as all materials associated with the roof trusses are manufactured to exact measurements, making reproduction of the same frame easy and quick as many times as required. The steel frames are then fitted and assembled together without the need for jigging, welding and/or cutting.

Production Process

The production of steel frames involves the use of a computer-controlled roll forming machine

and computerized punching, countersinking and cutting. Steel coils of Zincalume or galvanized coated sheet steel are fed through a roll forming machine to produce channels.

Prior to roll forming, the details of the house frame to be manufactured are transcribed into the computer software package. The software package provides data on cutting and punching which is then fed into the computer which controls the roll forming and punching operations.

The end result is that each steel frame member (channel) is cut to size with holes punched to enable members to be later riveted together. These are the components, which can be transported as a flat (strapped together) packed.

Each member is printed with job and part number for ease of assembly eliminating the need for costly time jigging. The roll form machine can be programmed to continue the repetitious production of buildings as many times as required.

A house frame of 160 sqm can be produced through the roll form machine in three (3) to four (4) hours. Each section of wall and roof are packaged in individual bundles and have accompanying computer drawings for ease of identification and erection.

The drawings are simple and allow members to be assembled using hand held pneumatic riveting machine which installs high shear strength rivets or screws.

Once the steel frames are assembled together at the site, it will be bolted to the structure’s foundation or based. The purlins are then attached with self-drilling fasteners. The colored roof panels or sheathing are attached to the purlins. The side wall and/or end wall studding is installed. Finally, apply the exterior finish of choice to complete the structure’s shell.

1. Who buys and needs our product or service?

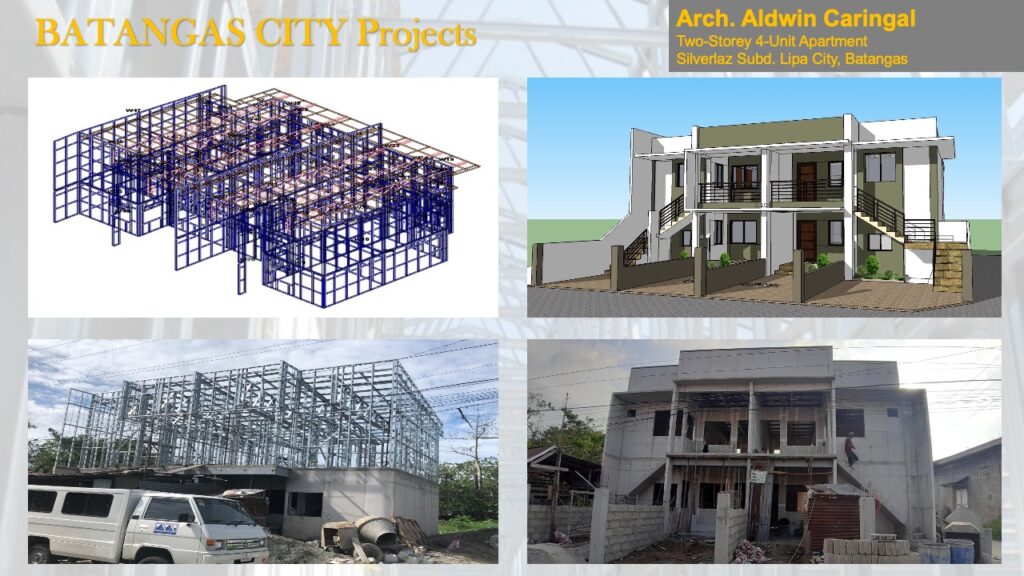

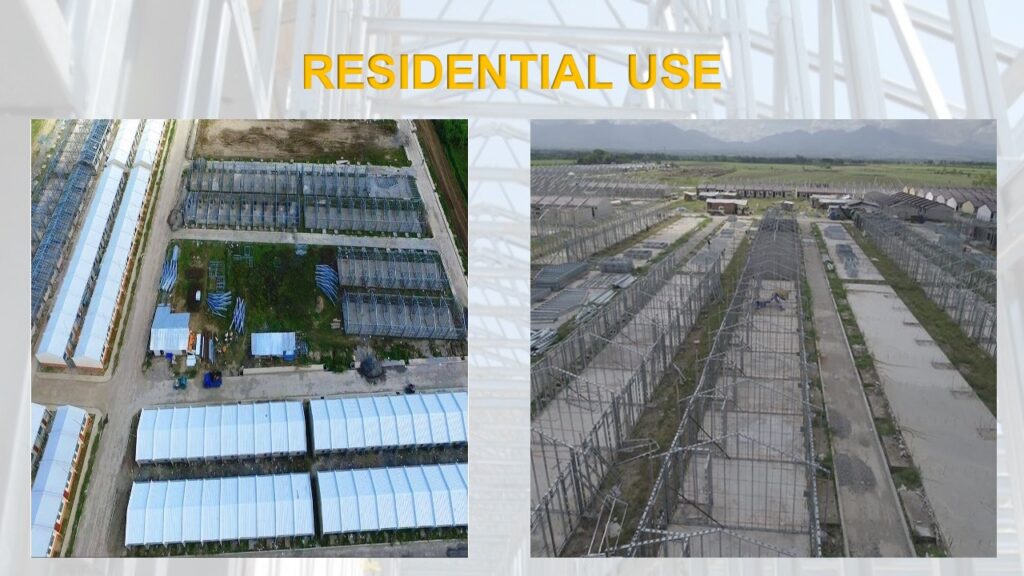

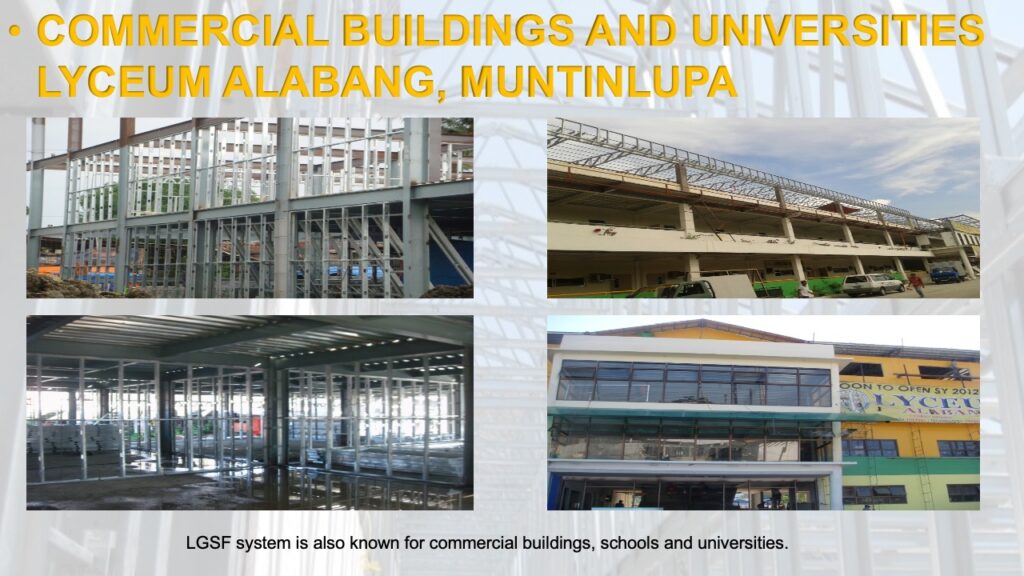

CapitalHomes Steel Framing Tech focuses on stakeholders in the Philippine construction market with special emphasis on those interested in light gauge steel residential houses, school classrooms, commercial/office buildings, related products and services.

Broken down below is CAPITALHOMES’ market groups:

Market groups above are defined in its general terms. These are clients who want to engage in alternative building systems, people who like steel and metal. Likewise, these are clients who are interested in speed of work without compromising quality and durability.

2. Size of the market

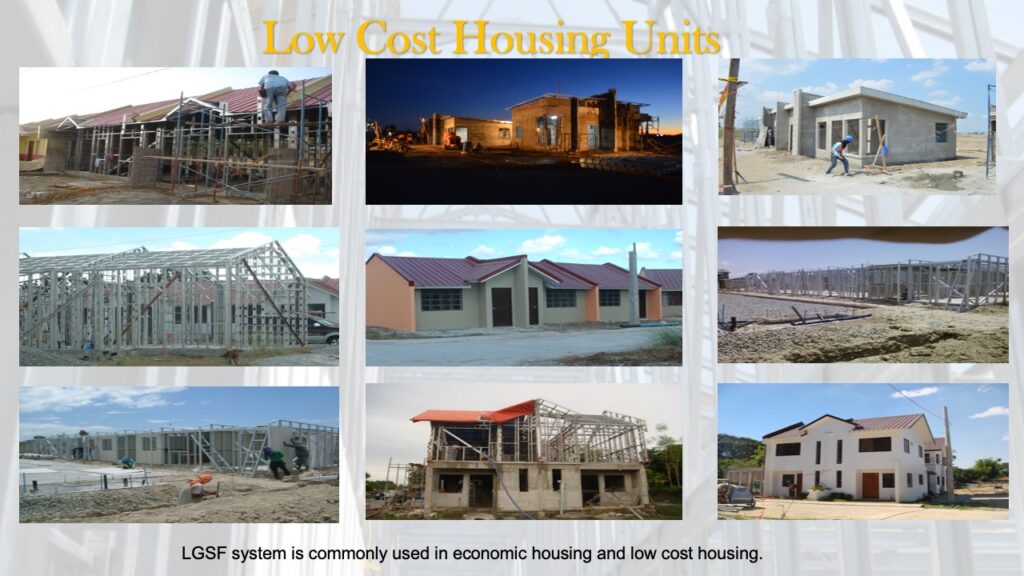

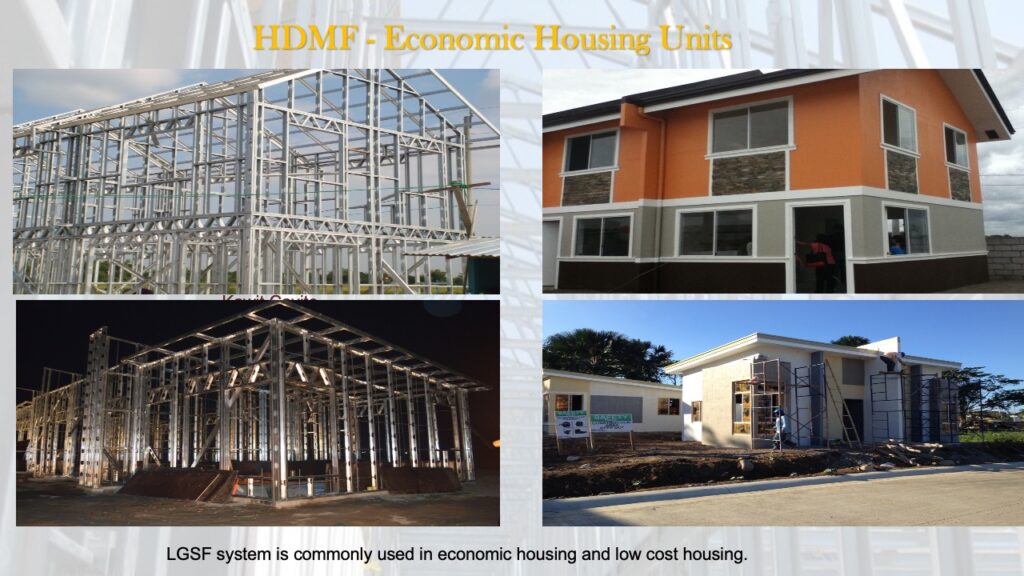

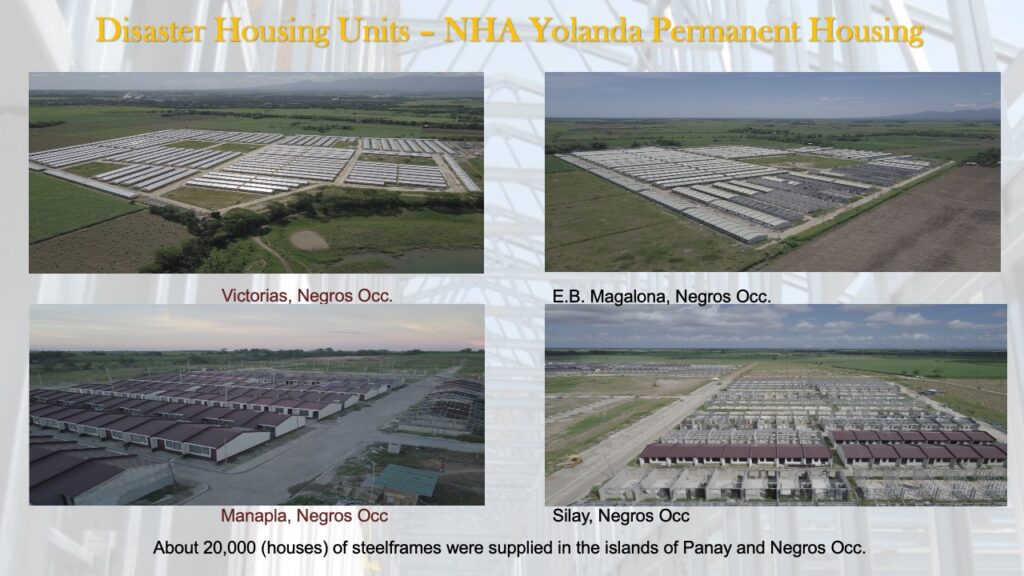

The country has a housing backlog of around six (6) million units. This figure suggests that around thirty (30) million Filipinos, at an average of five (5) members per family, are in need of decent homes of their own. Moreover, the housing backlog, as projected, continues to rise by three hundred fifty thousand units per annum primarily due to population growth and occurrence of natural and man-made disasters like typhoon, earthquake, landslide, floods, fire and terrorism. The foregoing data are based on the Philippine Development Plan published by the Housing and Urban Development Coordinating Council (HUDCC) and the report presented by the Subdivision and Housing Developers Association, Inc. (SHDA) entitled Philippine Housing Industry Roadmap: 2012-2030 to the Bureau of Investment.

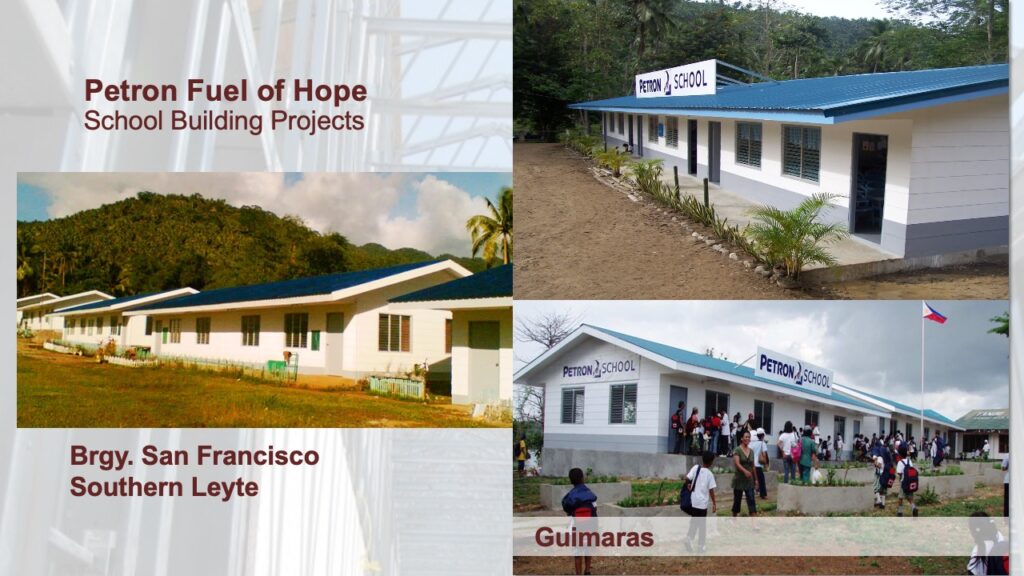

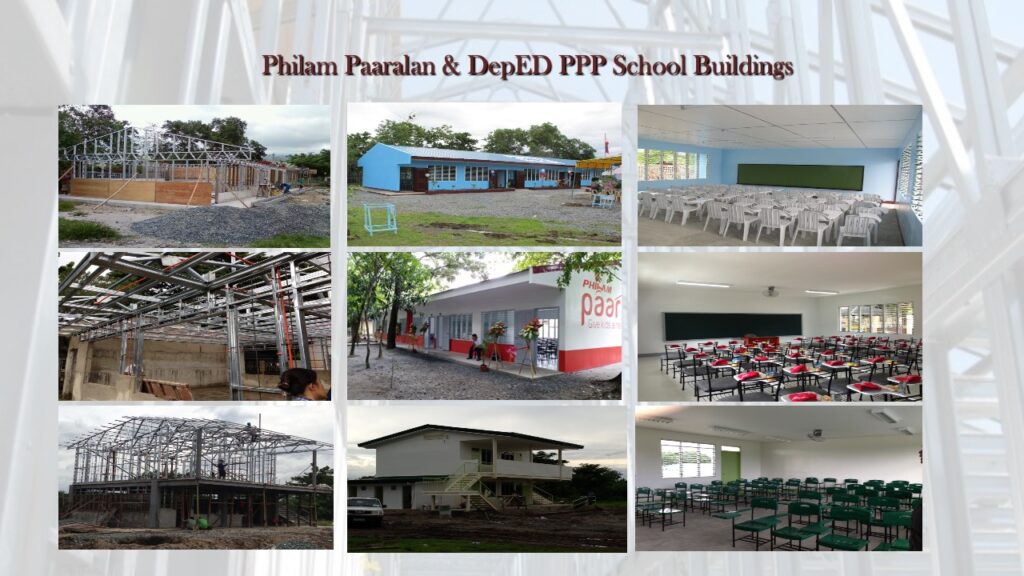

The school classrooms on the other hand is basically placed to NGOs and/or Foundations whose advocacy is to build classrooms nationwide in a bigger scale. The Department of Education estimates a shortage of 47,000 classrooms (ideal size of 40-45 students per classroom) as of this year and will continue to increase if not address immediately as student population rise by 6% annually. The steel framing is best fit for classrooms builders because they can utilize unskilled labor and/or volunteers without the need for special tools or equipment.

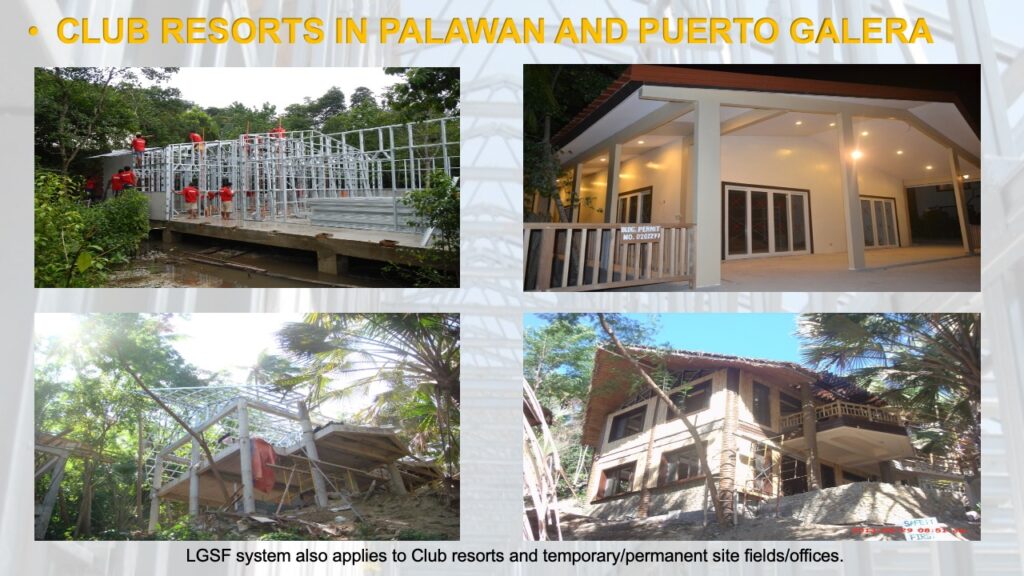

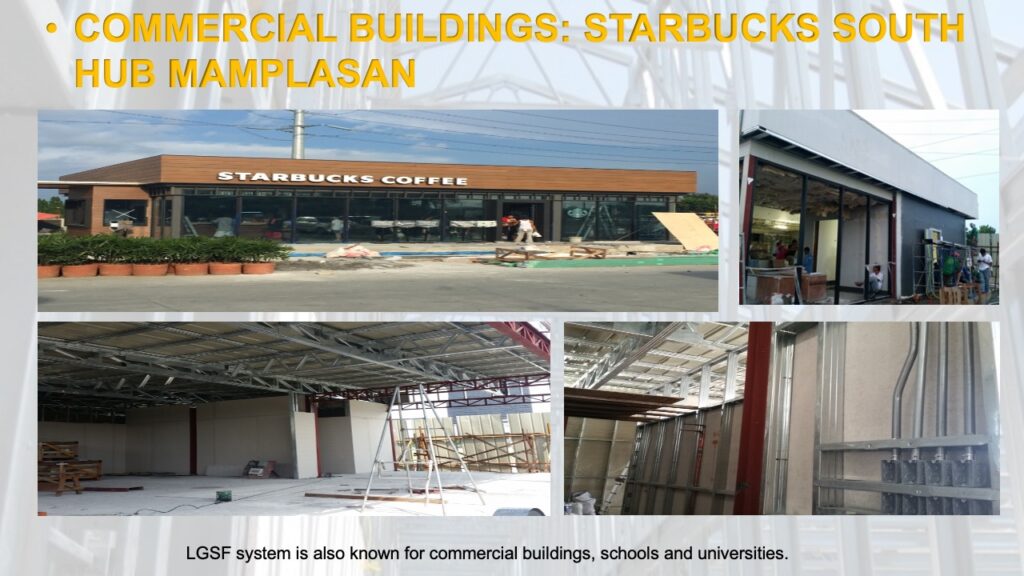

Finally, the requirement for commercial/office buildings are also growing given the economic boom that the country is experiencing. Fast food chains and restaurants are starting to be put up on rapidly progressing towns and provinces. The steel framing is suited for drywall partitions and ceilings. Commercial building construction can be cost effective in the long run because of its design technique and construction methodology.

3. Growth potential

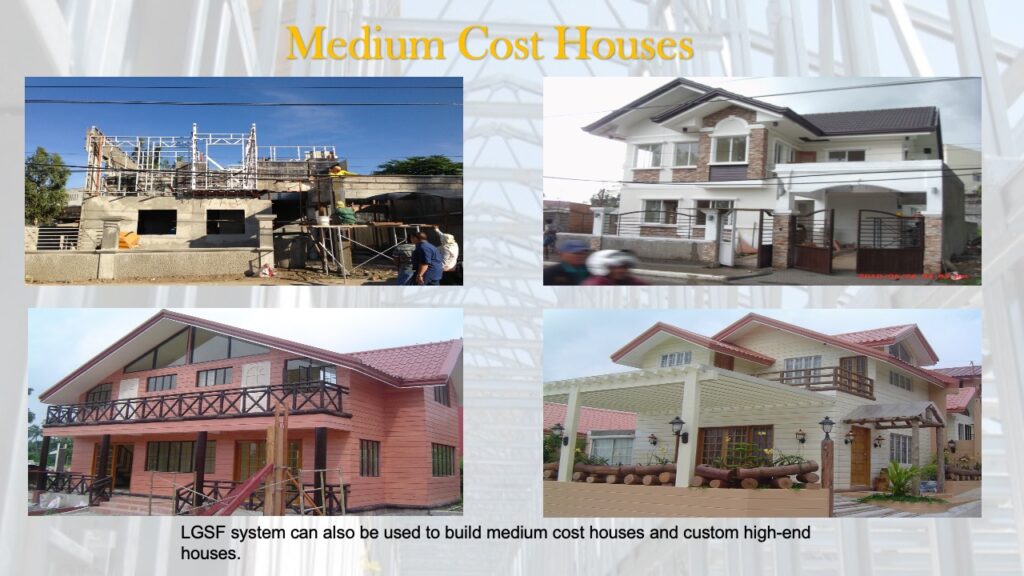

The CapitalHomes Light Gauge Steel Framing Technology is still in the infancy stage in the Philippines. This barely captures around 3% market share of the construction industry. The biggest share of the pie is being occupied by conventional/traditional methods while the rest are held by other technologies like pre-cast/pre-fabricated concrete, permaforms, etc. However, more and more industry players have started to patronize our technology due to cost savings, construction efficiency, and better quality and strength, thus bringing bigger potential for growth.

Advantages of CapitalHomes Steel Frame Technology

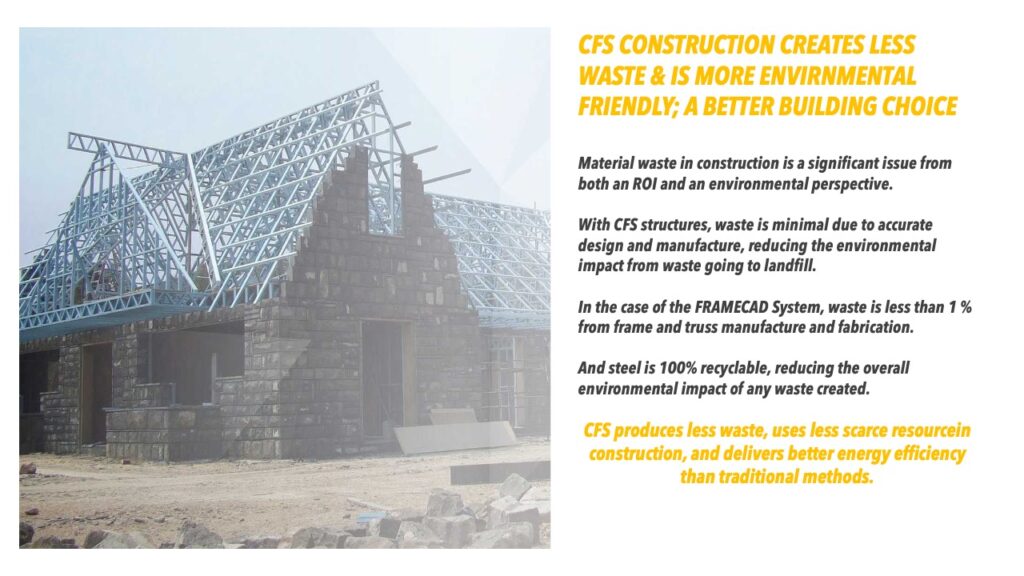

It is environment friendly. Its consumption benefits the environment because it discourages the use of standing timber resources as construction materials. And since it is not made of wood, the structure is resistant to termites of every type. CapitalHomes’ Steel frame is made from 66% recycled steel.

It is strong and will stay true to form without maintenance or treatment. The steel has hot-dipped metal coating that resists corrosion; unlike wood framing, it will not warp, rot, buckle, split, splinter. It is strong and rigid and it won’t cause cracking in the wall, nail popping or window and door jamming.

It can be engineered to withstand a range of wind speeds of up to 250 kph. Also, under stable floor conditions, the frame will suffer minimal damage during an earthquake. In cyclonic areas, it incorporates the use of heavier steel members with specially-designed walls and roof framing.

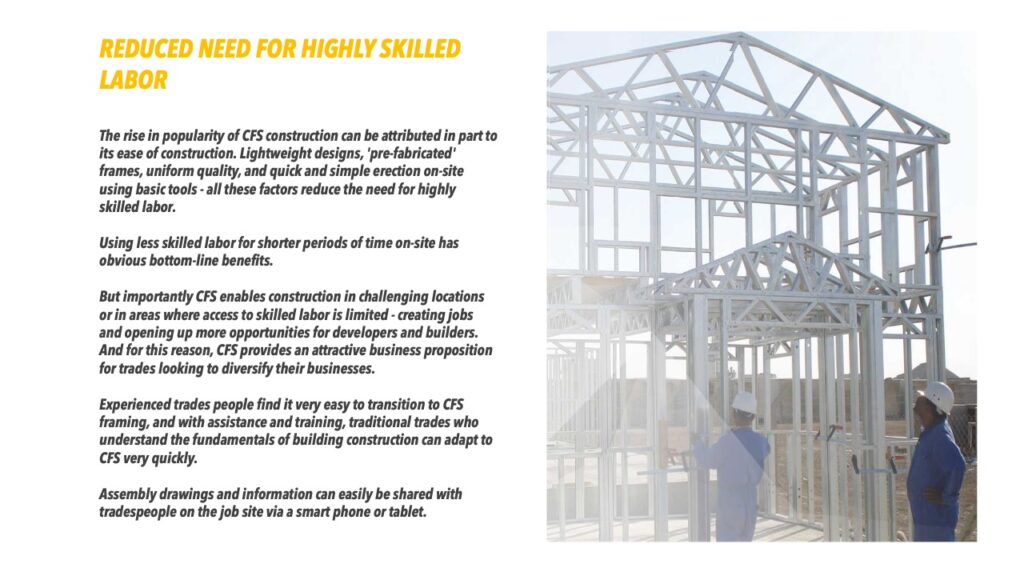

It can easily be delivered, assembled and erected at project site wherein works are mostly done by laborers and not skilled workers.

It is compatible with other building materials and can be used with most current building materials, installing plasterboard linings and wood fittings present no problems either; the usual floor, wall and ceiling materials can be easily and quickly placed. The exterior walls and roof trusses may be fitted with many choices of locally-produced materials and coverings.

It does not burn and offers greater fire protection.

It gives more freedom and flexibility to prospective clients as far as design,

materials, size and shape of a structure are concerned. The superior strength of steel also negates the need for “load-bearing” interior walls, allowing open and clear span interiors that can be decorated according to the house owner’s wishes.

The frame may be used for two story and buildings up to maximum height of three meters, i.e.: houses, schools, personnel barracks for army, police, transmigration programs, on-site housing for mine development, commercial stores, temporary facilities, resort cabanas, building projects etc.

It reduces building delays because the steel frames are made to exact specifications in the fabrication workshop.

Since steel is much stronger than wood, fewer pieces are needed to build a highly- stable frame. Light gauge steel is cheaper per linear meter compared to Concrete Hollow Blocks (CHB), and is easier and faster to set up – the frames for an average- sized house are light enough to be placed into position by three men in around two days.